Space Qualification and Acceptance testing

The objective of Qualification and Acceptance testing is to identify possible design flaws during the development process by simulating the launch vehicle ground and flight environmental loads including space and upper atmosphere conditions. Testing is required for all nanosatellite components as well as the full spacecraft assembly, to ensure the spacecraft meets the performance criteria for a forthcoming mission and all applicable CubeSat standards.

Serenum as a part of VZLU group provides a complex set of design verification services, including:

- Design of custom test plans and procedures, considering spacecraft mission conditions

- Custom design and manufacture of test GSE

- Environmental testing

- Vibration and Shock testing

- Thermal Vacuum Cycling

- ISO 6 Cleanroom and ISO 8 Cleanroom available for satellite assembly and payload integration

Mechanical tests

Vibration and shock testing

Shock and vibration testing verify spacecraft performance under extreme conditions. We provide the full spectrum of mechanical testing necessary for Qualification, Proto-flight, and Acceptance of spacecraft.

Test types:

- Resonance search

- Quasistatic

- Sine

- Random

- Shock

Climatic tests

Thermal vacuum testing

A thermal vacuum chamber allows the simulation of conditions in space including both temperature and vacuum. The purpose of testing is to reveal possible deficiencies of the design by cycling very high and very low temperatures in a space-like environment of the chamber.

Services:

- Thermal Vacuum Cycling

- Thermal Vacuum Bake Out

TV chamber specification:

Chamber volume: 1000 mm x 1000 mm x 1000 mm

TV tunnel chamber extension available: 10 m x 200 mm diameter

Thermal Vacuum tests are performed within ISO 6 Cleanroom.

Maximum external dimensions for parts to be placed into the chamber: 950mm x 870mm x 780mm

Vacuum value < 10-3 Pa

Temperature values:

- Range: -60 ºC – +150 ºC

- Accuracy: 0.1 ºC

- Regulated rate: 1 °C/min

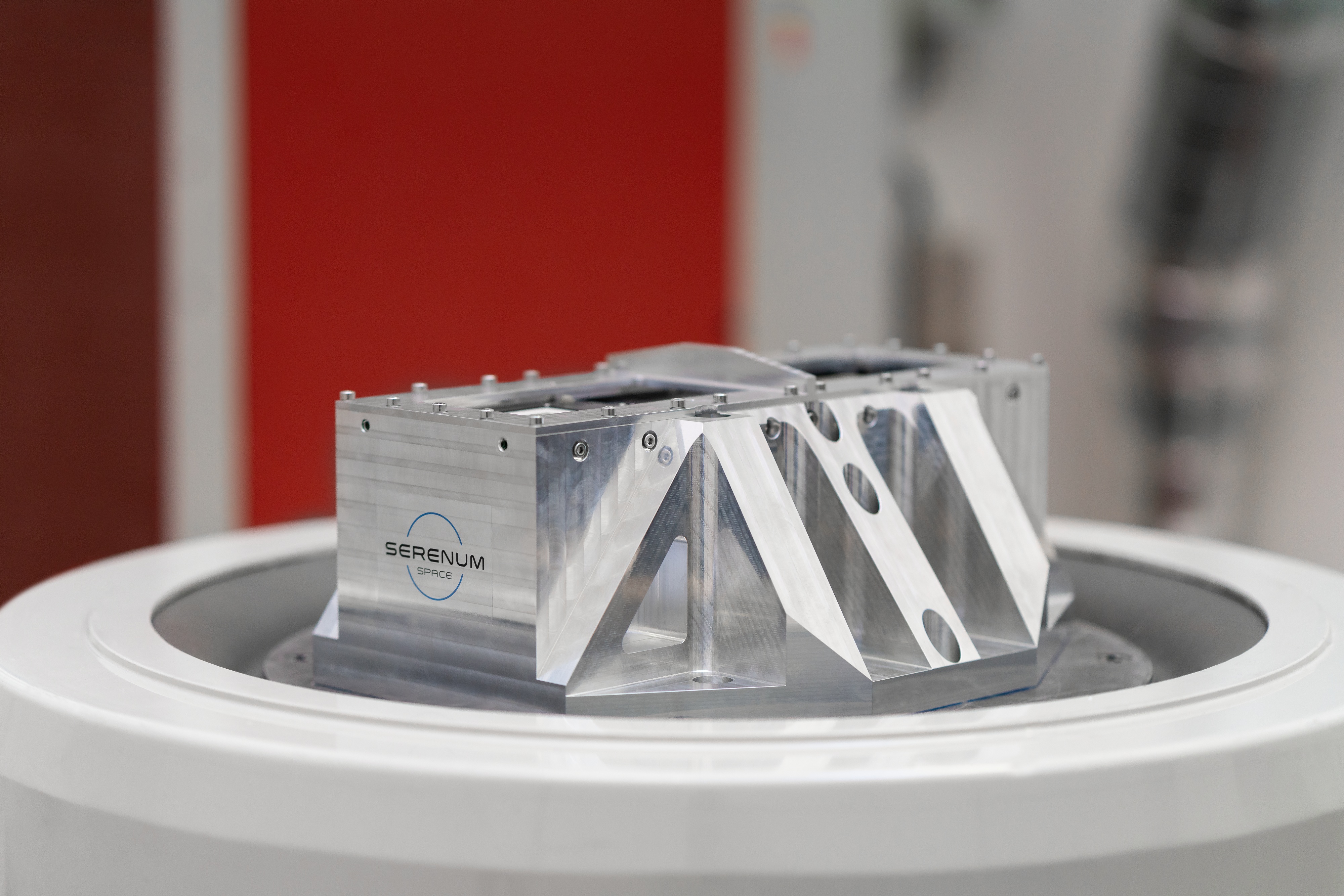

Cleanroom

A Cleanroom is dust, temperature, and humidity controlled environment that protects satellites and spacecraft components from contamination during its development, construction, and testing. SERENUM operates class ISO 8 and ISO 6 Cleanrooms. In general, an ISO 8 room is sufficient for satellite platform assembling, while payloads usually require ISO 6 environment.

Cleanliness: ISO 8 (equivalent to FED STD 209E Class 100,000), ISO 6 (equivalent to FED STD 209E Class 1,000),

Maximum dimensions for parts to be assembled based on the room size:

- ISO 8 Cleanroom: 31,25 m2; 5,6m x 5,0m x 2,6m + 2,5m x 1,3m x 2,6m

- ISO 6 Cleanroom: 31,50 m2; 5,6m x 5,0m x 2,6m + 2,5m x 1,4m x 2,6m

References

Working with us means capitalizing from our well-equipped testing facilities and years of experience of experts from SERENUM and affiliate companies VZLU and VZLU Test with Satellite testing and a wide variety of specific test campaigns ranging from small, single-purpose tasks to complex projects.

Examples:

- Proba 3 qualification and acceptance testing of ASPIICS Coronagraph Front Door Assembly flight model

- SWARM qualification and acceptance testing of three microaccelerometer instrument flight units

- JUICE concurrent design qualification of radiation shielding and magnetometer arm (length over 10 m)

- EUCLID concurrent design qualification of mechanical elements

- ARIANE 6 structural testing of booster structural part, strength analysis, and design of launcher structural parts, in cooperation with MT Aerospace

- FLPP CFD and flutter calculations and wind tunnel experiments performed on scaled composite aeroelastic models in subsonic, transonic, and supersonic regimes.

- CubeSats qualification and acceptance testing for multiple CubeSats and payloads

Standards:

- ECSS-E-ST-10-03C Testing

- EN 60068-2-57, 59, 64

- RTCA/DO-160

- MIL-STD-810

Photo credits: VZLU, a.s., VZLU TEST, a.s.